Product Categories

- (0086)-13763302313

- (0086)-752-6355217

- (0086)-752-6355216

Product Details

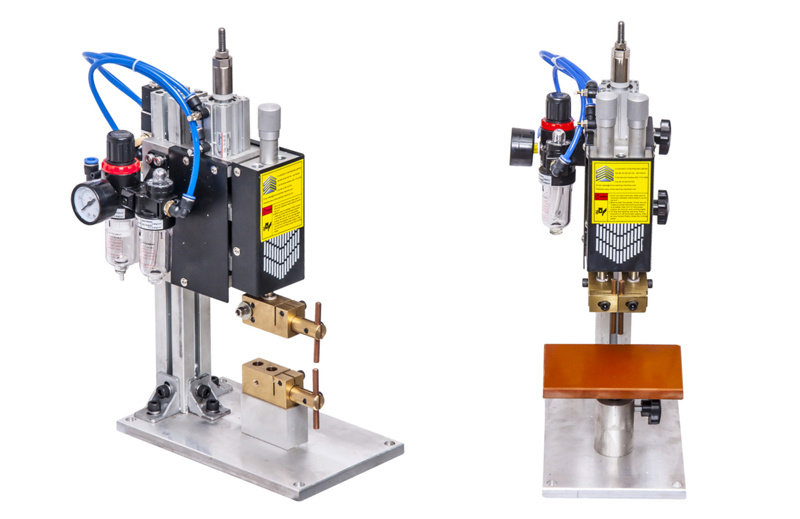

DP-3KW Dual Pulse Capacitive Discharge DC Welder

Keywords:

Description

Introduction

Dual Pulse Series Capacitor Discharge DC Welding System includes two main parts:DC Welding Power Source and Pneumatic Spot Welding Head. Power Source Part can work with other automatic welding tooling and fixture, the Welding Head can also work with other kind of welding power supply.

DC Welding Power Source Specification:

DC Welding Power Supply adopt the microprocessor controlling system, specially designed for precision resistance welding,can output the stable and consistent welding energy for different workpieces,not affected by the fluctuation of input voltage.

Dual Pulse Function can eliminate the welding surface differences,also can store many groups of welding schedules and welding parameters.Because it can rapidly produce high peak welding energy in a very short period of time, the welding time is very short,This function is especially important when welding highly conductive materials such as copper,brass.aluminum,nickel,compared to the general.

AC power and the general inverter welding source,it has the particularly good welding quality,the welding deformation is the smallest.

Main Applications:

①Communication equipment: battery cans,battery prismatic tab,battery, mobile phone, mobile phone battery core,mobile hardware etc.

②Electronic components: elec.capacitor,connecting cable, sensor, resistor, fuse, semiconductor devices, weld electronic foot to welding wire, weld the line to the terminal etc.

③Digital products: notebook computer, digital camera, MP3, computer memory cell head etc.

④Household appliances: socket, electric shielding shell,and so on.

⑤Automotive: flash, relay, filament,and so on.

⑥Electromechanical devices: contactor, breaker, motor, bulbs extraction lug etc.

⑦Metal products: medical equipment, lamps and lanterns, badges, headdress, jewelry and so on.

⑧Aerospace, precision metal parts, instruments, metal connectors, Honeycomb Tacking,induction device etc.

Pneumatic Spot Welding Head

Precision Welding Head,including two models:Type A:Upper and Lower Type Welding Electrode and Type B:Single Side Welding With Parallel Electrode.It has the spring precisely adjusted function,good dynamic,strong stability,convenient adjustment,can adjust up and down,left and right,4directions of regulation,make sure to get the best welding quality.

Type A:Upper and Lower Type inline Welding Electrode.

Type A:Upper and Lower Type inline Welding Electrode And Type B:Single Side Welding With Parallel Electode.

Main Specification List:

|

焊Welding Power Supply

|

Rated Input Voltage

|

220V/240V 50Hz/60Hz

|

|

Input Power

|

3KVA

|

|

|

Max Capacitance Energy

|

250J

|

|

|

Main Electrical Switch

|

500V,10A

|

|

|

Power Source Safety Fuse

|

15A

|

|

|

Welding Contacting Cable

|

≥4mm2

|

|

|

Power Source Earth Wire

|

≥2mm2

|

|

|

Welding Head

|

Pressure Mode

|

Pneumatic + Spring

|

|

Welding Pressure

|

0.5Mpa

|

|

|

Air Compressor

|

>1HP

|

|

|

Input Air Tube Diameter

|

φ8mm

|

|

|

Welding Electrode Stroke

|

20mm

|

|

|

Welding Throat Gap

|

60mm

|

|

|

Welding Arm Throat

|

80mm

|

|

|

Welding Electrode Diameter

|

6mm

|

More Products

Message

Get prices and free samples now!

GUANGDONG DUROPOWER INDUSTRIES LTD

Durowelder Industrial Zone,Huzhen Street,Boluo District,516139,Huizhou City,China

DuroPower & DuroWelder

GUANGZHOU DUROWELDER LIMITED

Buiding 3,No. 29,Lixin 8th Avenue,Zengcheng District,Guangzhou City,511340,China